Thanks to their high load capacity, rothe erde® roller bearing can be used for a wide range of applications. The areas of deployment range from excavators and cranes, opencast mining and wind turbines, to antennae. Other fields of application include smelting engineering and general engineering.

Our products

thyssenkrupp rothe erde combination bearings are made of ball and roller raceways. This design allows for the advantages of balls and rollers to be combined. Here, the roller raceway transmits the axial loads and the ball raceway the radial loads. The result is a very high load transfer level and a long service life.

Our combination bearings are used where no high tilting torques have to be transmitted. In such cases, combination bearings offer an economically superior alternative to three-row roller-bearing slewing rings.

Since axial roller bearings are not self-retaining, they are better suited to being used with concentrically-acting loads. Typical deployment areas for these bearings include opencast mining, smelting engineering and in lathes.

thyssenkrupp rothe erde radial roller bearings are not torque bearings. Since they are not self-retaining, they are better suited to being used with concentrically-acting loads. Machine tools are a typical area of deployment for these bearings.

Our three-row roller-bearing slewing rings are the perfect solution to your bearing needs. They combine the ability to absorb heavy loads with the promise of a long service life. Three-row roller-bearing slewing rings can be purchased either with exterior or interior gearing or entirely without gearing.

Typical deployment areas include in excavators, crane and opencast mining, wind turbines and antennae. Other fields of application include smelting engineering and general engineering.

An additional radial raceway is what differentiates the four-row roller-bearing slewing ring from the three-row version. Originally, they were designed to transmit higher radial loads through the companion structure. A classic example of this is their use in offshore applications, such as in deck cranes.

Tapered roller bearings are amongst the most sophisticated products made by thyssenkrupp rothe erde as far as manufacturing is concerned. In order to ensure the highest production standards are achieved, our tapered roller bearings combine the highest quality material properties with unique raceway inserts.

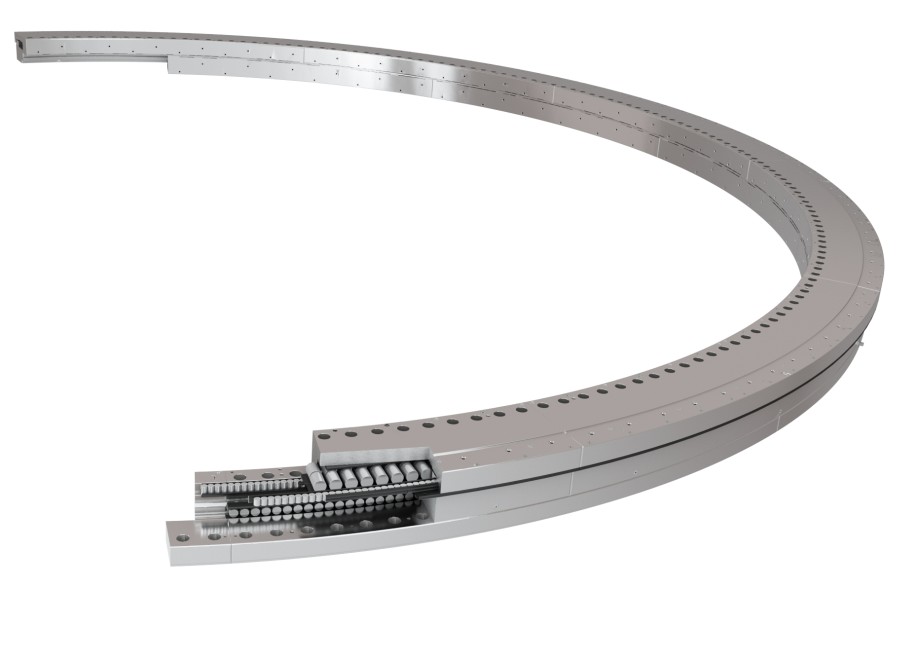

If ball bearings become insufficiently dimensioned, and the use of a three-row roller bearing is economical but not sensible, cross roller bearings are the perfect technical solution. Since they only have one raceway, the rollers are offset. This guarantees the transmission of tilting torques.

thyssenkrupp rothe erde cross roller bearings have a wide variety of applications: These range from acting as the bearings for antennae, where their precision of execution is used, to the construction of excavators.

- Home

- Products

- rothe erde® slewing bearings

- Roller bearing

/thyssenkrupp_logo_claim_d.svg)