Smelting works engineering

A smelting or steelworks plant serves to produce unrefined iron and steel out of iron ore. The term, smelting technology, describes the process of producing steel, as well as the applications and machines used in doing so. These machines are equipped with both ball bearing and roller bearing slewing rings. Almost all well-known manufacturers of different systems for smelting technology trust the individually developed and manufactured products made by thyssenkrupp rothe erde.

Our solutions in the smelting technology sector

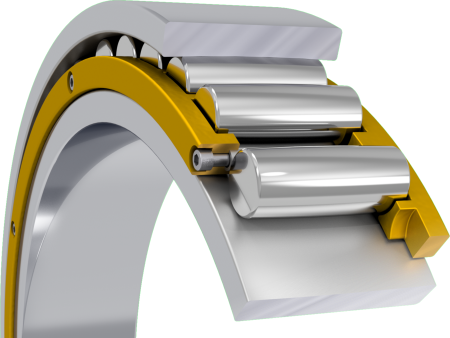

Strip rolling mills are used to reduce the strip thickness of plates and strips. Bearings made by thyssenkrupp rothe erde are used in rolling mills as part of their warm and cold rolling process. Here, they are exposed to particularly harsh conditions: In addition to the extreme temperatures, the strong rolling forces particularly impact all components. Bearings for this area of application thus require high load-bearing capacities to absorb resulting rolling forces. We develop, design, and manufacture these down to the tiniest detail so that our customers are provided with a financially-optimal design, which also ensures a maximum of safety.

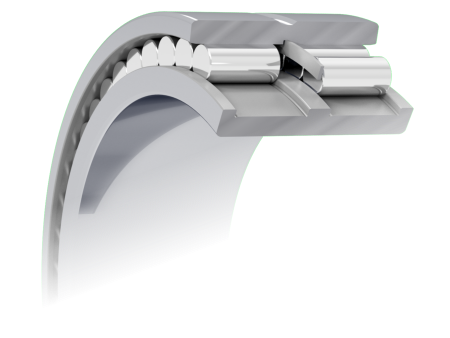

Converters are used to produce steel out of unrefined iron. To ensure that several hundred ton-heavy skip vessels remain mobile, converter bearings are used. Very slow swivel movements combined with regular shock loads demand a very high static load-bearing capacity of the bearing. Our converter bearings for this sector are designed to be able to withstand high loads against the backdrop of a low number of rotations, whilst reducing the risk of permanent deformation.

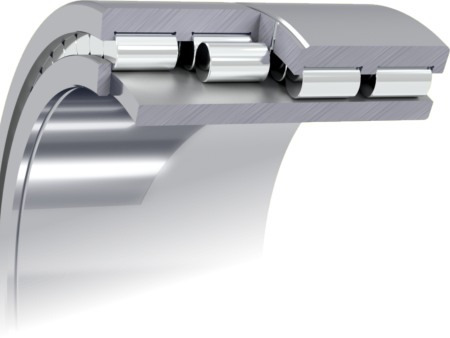

In section mills, steel is reshaped by large rollers into, for example, rails, sections and heavy profiles. Bearings in section mills are exposed to considerable forces. To better distribute the loads, multi-row bearings are often used for this scope of application. Our cylindrical roller bearings and tapered roller bearings are among the most established bearing designs in section mills.

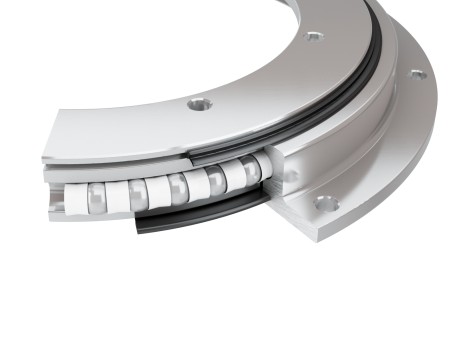

The ladle turret and swifter are in permanent use and set in their loading position. Roller bearing slewing rings made by thyssenkrupp rothe erde are used here: They guarantee the continuous operation of the continuous casting line and can withstand the high loads. This means that they can be used for several decades.

To use old scrap steel for new products, it is first melted down in an electric arc furnace. The swivelling cover of this oven is an elementary part of this process. In order to avoid negatively impacting the process, it must be usable over the long term. and under extreme environmental conditions. This is why we develop bearings here at thyssenkrupp rothe erde, which are specifically made to meet the needs of the smelting technology sector in terms of heat resistance and durability.

In steelmaking, the carbon found in the unrefined iron is oxidised by the targeted supplying of oxygen. Lance slewing mechanisms are used in this process. thyssenkrupp rothe erde develops slewing bearings especially for this scope of application, which can even safely withstand the extreme environmental temperatures.

Swivel joints are movable parts of a pipe. They are used to transport fluids or gases between two system parts that move relative to each other. This presents a unique challenge during construction: The swivel joints must be able to carry out pivotal movements and slow swivel movements simultaneously, within a radius of 360°.

Bearings made by thyssenkrupp rothe erde are used for this as they are developed to be able to not only easily absorb the pressure load, but also external forces.

To allow molten unrefined iron to run from the furnace, tapping is carried out at regular intervals. For this, the lower lock, the so-called needle hole of the furnace, is opened. The needle hole drilling and plug machines must be able to guarantee both the precise drilling of the needle canal and its subsequent plugging.

Renowned manufacturers around the globe rely on thyssenkrupp rothe erde and use our slewing bearings, which have been especially designed to meet these requirements.

Rolling ingots and extrusion billets are manufactured in continuous casting plants. Depending on the material being used, very high temperatures may prevail during production. Therefore, in order for operation to be reliably maintained, our bearings must be highly heat resistant. Since continuous casting plants are used in various different locations, other features are also important: Multi-row roller bearings used for loading and unloading ladle turrets must be able to absorb moments of high levels of tilting and shock loads. Bearings which are used as part of the roller guide must, in turn, be designed for low numbers of rotations and high loads.

/thyssenkrupp_logo_claim_d.svg)